百鳥朝鳳作品介紹

- 發布日期:

- 最後更新日期:114-10-14

- 資料點閱次數:499

百鳥朝鳳作品介紹

Introduction to “A Hundred Birds Paying Homage to the Phoenix”

作品寓意|Meaning of the Work

〈百鳥朝鳳〉由國寶級大師陳甫強指導新竹監獄螺鈿技訓班4名學員製作,以珍稀的螺鈿工藝描摹群鳥向鳳凰歸附的和諧景象。作品寓意為鳳凰昂首向天,百鳥環繞飛翔;鳳凰代表重生,百鳥象徵社會的多元包容,意指即使在高牆之內,藝術的種子仍能生根發芽,綻放重生之光。

Created under the guidance of master artist Chen Fu-qiang, four trainees from the Hsinchu Prison mother-of-pearl inlay class made this work using a rare traditional craft. It depicts birds gathering around the phoenix in harmony. The work shows the phoenix lifting its head toward the sky while many birds circle in flight. The phoenix stands for rebirth, and the many birds suggest a diverse and inclusive society. It suggests that even within high walls, the seed of art can take root and shine with renewal.

作品觀賞指南|Viewing Guide

本作品含木框長180公分,寬93公分,厚8公分,約以3,500片貝殼製作而成,並經過詳細的配色設計,任何一步失手都可能前功盡棄。欣賞時建議走動、從不同角度觀看,可見貝殼在光線下折射出的不同光彩;亦可近看片縫,感受鳥羽、樹木、雲彩如何由細小片塊精密拼接,並細看不同鳥類的動態與神情,體會工匠細緻的表現。

Including the wooden frame, the work measures 180 × 93 × 8 cm. It was made with about 3,500 shell pieces and planned with careful color matching. A single misstep at any stage could ruin the work. We suggest walking and viewing from different angles; the shell shows different colors as the light changes. You can also look closely at the joints to see how the feathers, trees, and clouds are built from many small pieces, and observe the different poses and expressions of the birds to feel the artisan’s fine workmanship.

成立螺鈿班緣起|Origins of the Inlay Training Program

「螺鈿」又稱貝殼鑲嵌,為傳統鑲嵌技藝,意指將貝殼鑲入木頭或漆器;由於過去貝殼被視為財富象徵,螺鈿也成為家具上的華麗裝飾。

Luodian, also called mother-of-pearl inlay, is a traditional technique of setting shell into wood or lacquer. In the past, shells symbolized wealth, so this craft became a splendid decoration on furniture.

螺鈿約於1950年傳入台灣,當時新竹地區為家具重鎮,匯聚上百位資深師傅。惟因製作工序繁複且材料取得不易,使此傳統工藝漸面臨凋零與失傳危機。為復振並傳承螺鈿技藝,典獄長曾文欽親自拜訪新竹在地國寶級工藝大師陳甫強先生,將此傳統技藝帶入監獄,成立螺鈿工藝班。

The craft came to Taiwan around the 1950s, when Hsinchu was a furniture hub with many master craftsmen. Because the process is complex and materials are hard to obtain, the craft faced decline. To revive and pass on the skill, Warden Tseng Wen-chin invited Hsinchu’s renowned master Chen Fu-qiang to bring the technique into the prison and establish the inlay class.

螺鈿技法及工序|Techniques and Process

螺鈿技法可分為薄螺鈿與厚螺鈿兩種:薄螺鈿為將貝殼磨薄為貝片後切割,再以膠水或漆黏貼於木材或漆器表面,常見於日本漆器。

Luodian includes thin and thick methods. Thin inlay grinds shell thin, then cuts and glues it to the surface of wood or lacquer; it is common in Japanese lacquerware.

本監承襲厚螺鈿工藝,工序多達25道。製作厚螺鈿需將貝殼厚度保留於2至3毫米,在木面開挖約1.5~2毫米深的凹槽,將貝殼鑲嵌其中,再將表面研磨齊平。

Our workshop follows the thick inlay method, with about 25 steps. The shell keeps a thickness of about 2–3 mm. We carve recesses about 1.5–2 mm deep into the wood, set the shell pieces, and then level and polish the surface.

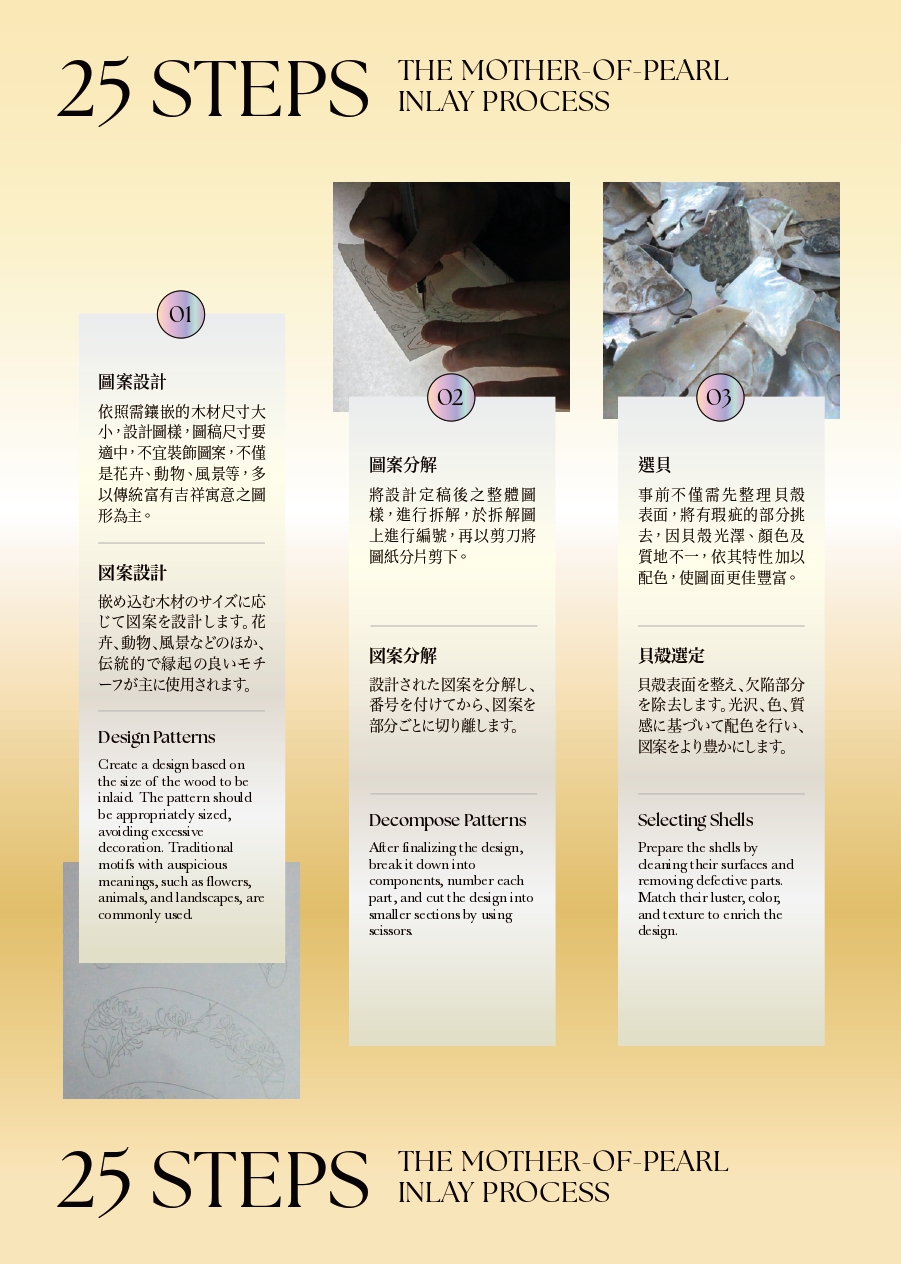

1.圖案設計:依木材尺寸設計圖樣,以花卉、動物、風景等具吉祥寓意之圖案為主。

1.Design Patterns: Create a design based on the size of the wood; use auspicious motifs.

2.圖案分解:將定稿圖樣分解、編號並剪成分件。

2.Decompose Patterns: Break down and number the design, cut into sections.

3.選貝:挑除瑕疵貝片,依光澤與色澤配貝,使圖面更豐富。

3.SelectingShells: Remove defective parts and match shells by luster and color for richness.

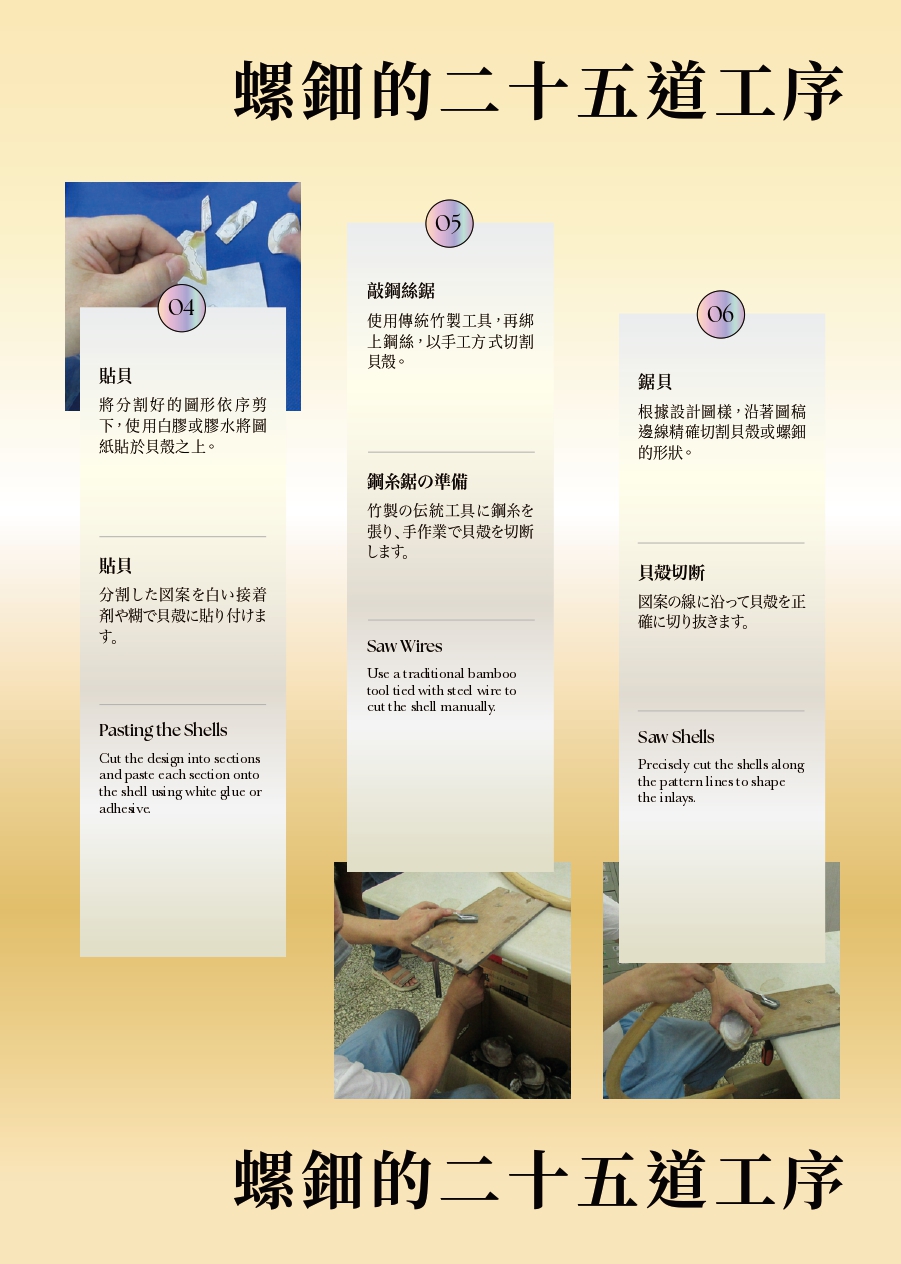

4.貼貝:將圖樣貼於貝殼上,準備切割。

4.Pasting the Shells: Paste the paper patterns onto the shells using glue.

5.鋼絲鋸:以竹製鋸弓張上鋼絲,備手工切割。

5.Saw Wires: Use a bamboo bow with steel wire to cut manually.

6.鋸貝:依圖線精確鋸出貝形。

6.Saw Shells:Cut along the pattern lines to form shell shapes.

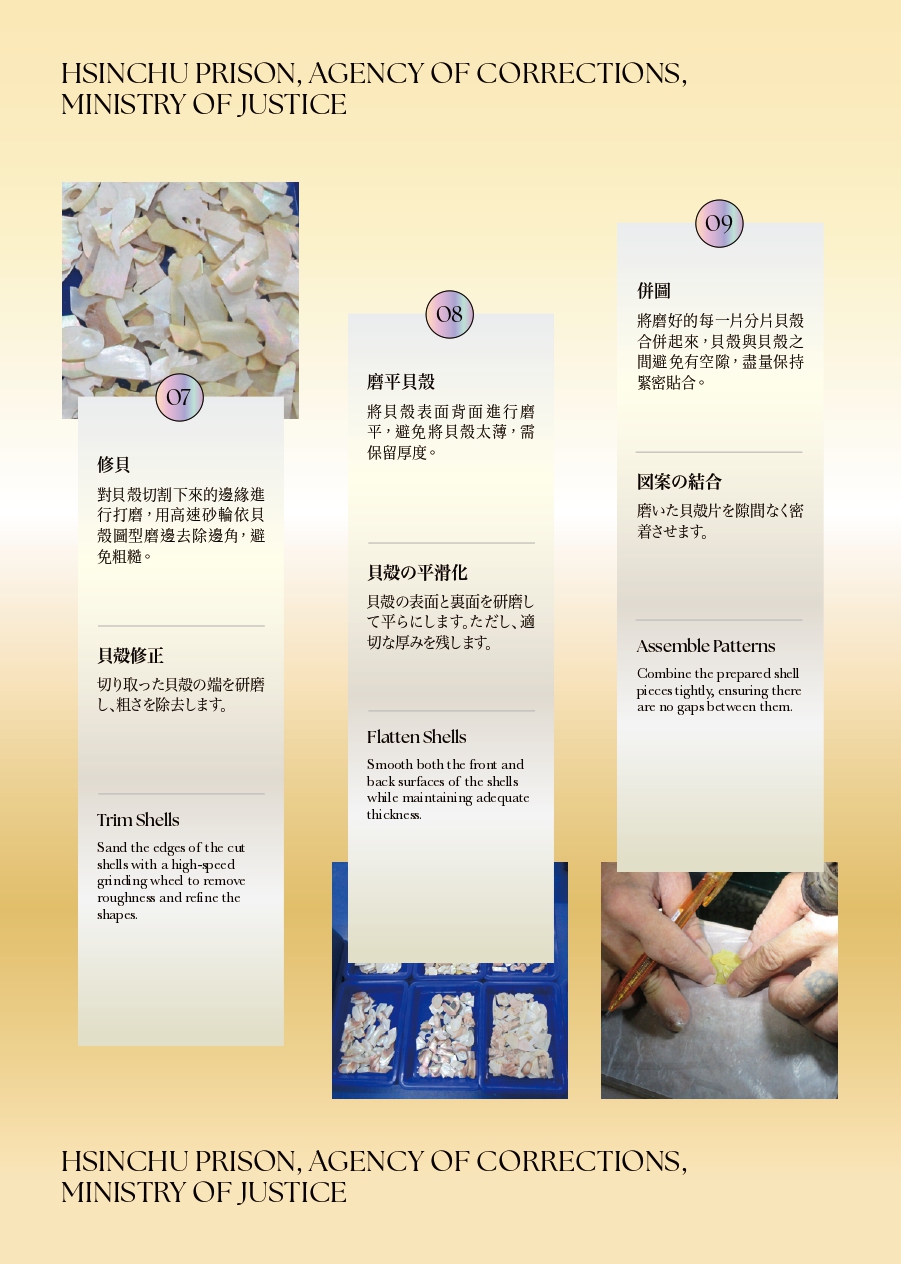

7.修貝:以砂輪磨邊,去除毛刺與粗糙。

7.Trim Shells: Sand the shell edges to smooth them.

8.磨平貝殼:磨平正反面,保持厚度。

8.Flatten Shells: Smooth both sides while maintaining adequate thickness.

9.併圖:將貝片緊密拼合,避免空隙。

9.Assemble Patterns: Combine shell pieces tightly without gaps.

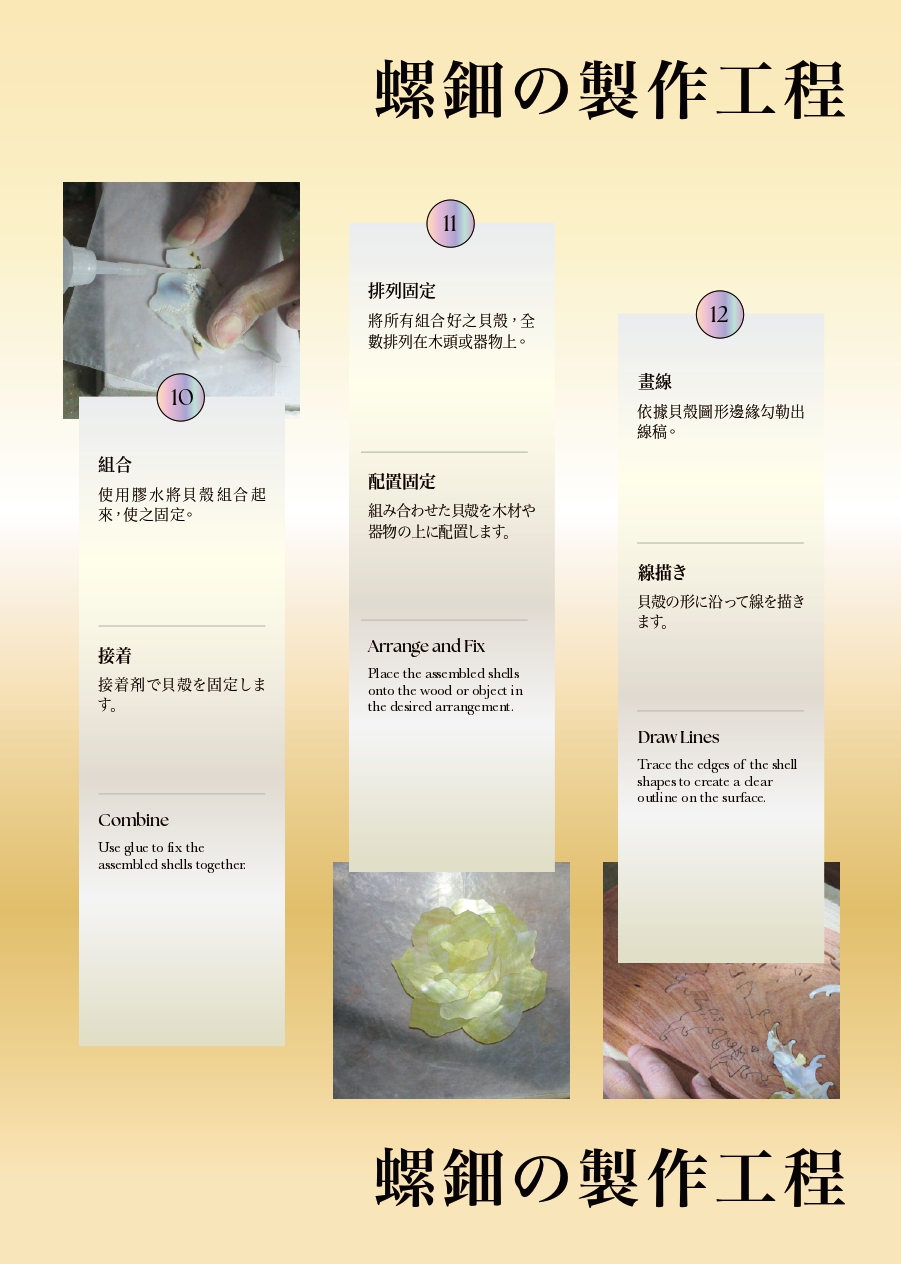

10.組合:用膠固定貝片成完整圖樣。

10.Combine: Use glue to fix assembled shells together.

11.排列固定:將組合好的貝片定位於木坯上。

11.Arrange & Fix: Arrange the shells onto the wood surface.

12.畫線:沿貝形邊緣描線作準。

12.DrawLines: Trace outlines of the shells for guidance.

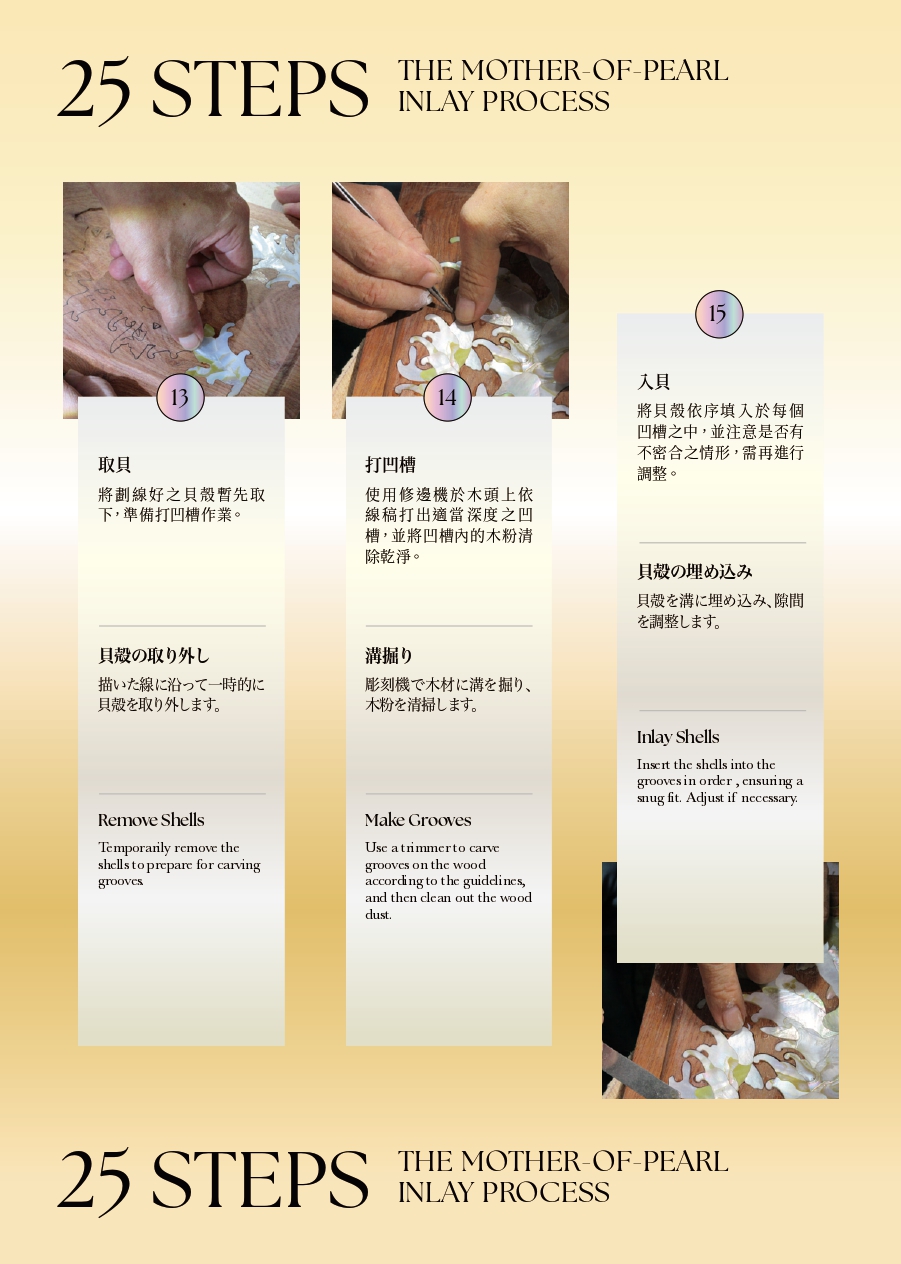

13.取貝:暫取下貝片,準備開槽。

13.Remove Shells: Temporarily remove shells for carving grooves.

14.打凹槽:用電木銑沿線開槽,清除木粉。

14.Make Grooves: Carve grooves with a router and clean dust.

15.入貝:將貝嵌入槽中並微調密合。

15.Inlay Shells: Insert shells into grooves, ensuring snug fit.

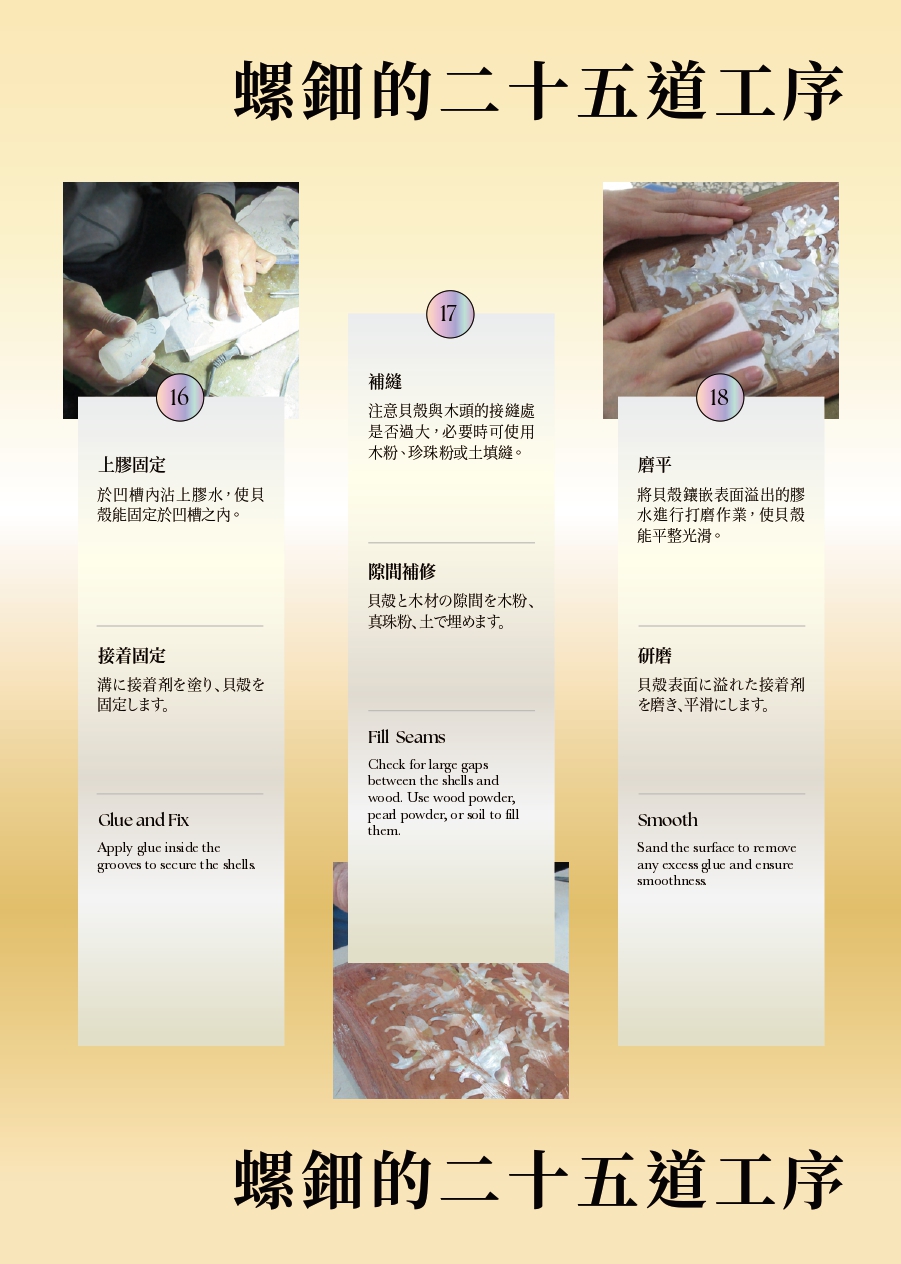

16.上膠固定:於槽內塗膠固定貝片。

16.Glue & Fix: Apply glue inside grooves to secure shells.

17.補縫:用木粉、珍珠粉或土填縫。

17.Fill Seams: Fill gaps with wood or pearl powder.

18.磨平:打磨去除溢膠,使面平整。

18.Smooth: Sand off excess glue for a smooth surface.

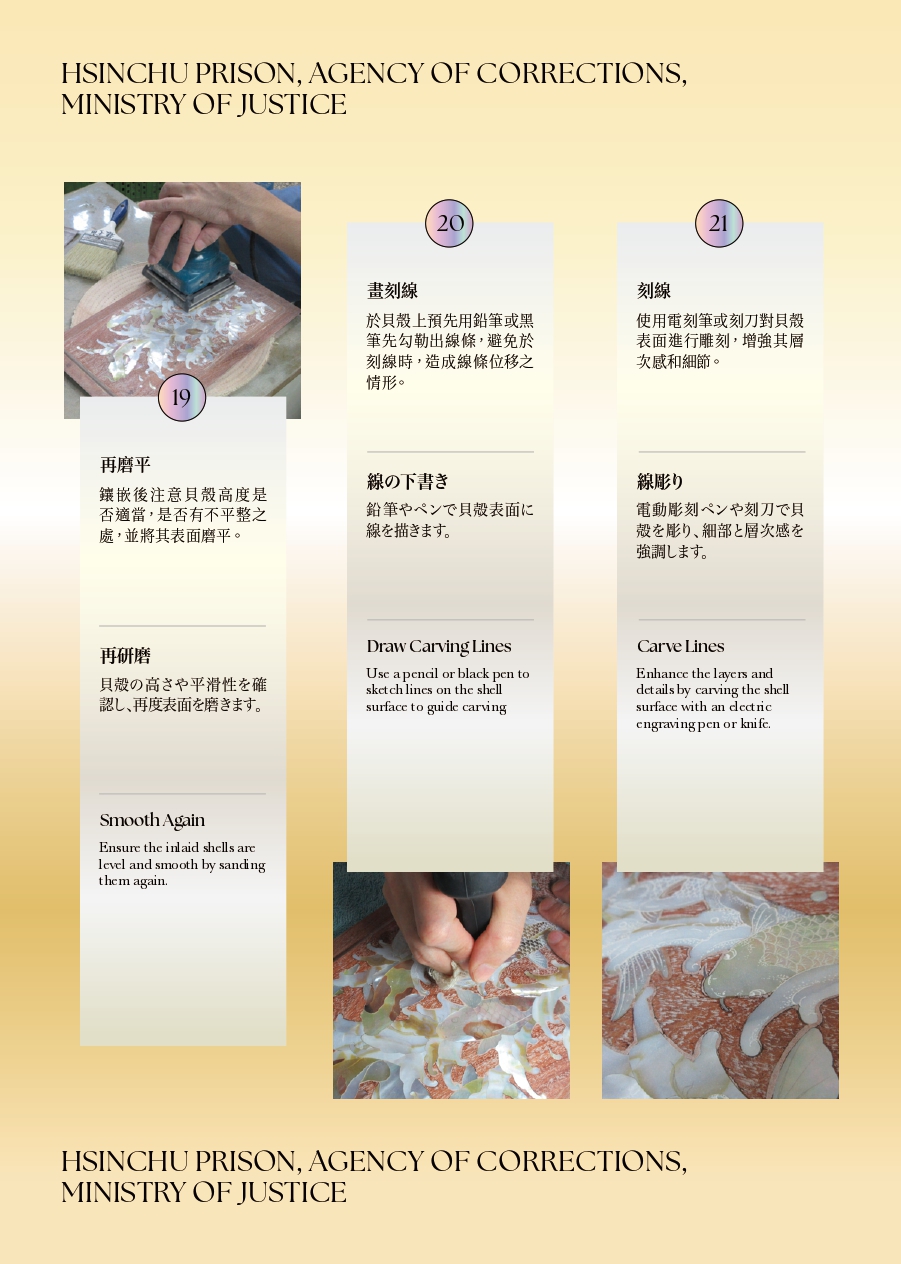

19.再磨平:確認高度與平整度再磨。

19.Smooth Again: Re-sand to level the inlaid surface.

20.畫刻線:以鉛筆預描刻線。

20.Draw Carving Lines: Sketch lines on the shells before carving.

21.刻線:用電刻筆刻出細節。

21.Carve Lines: Carve the surface for depth and details.

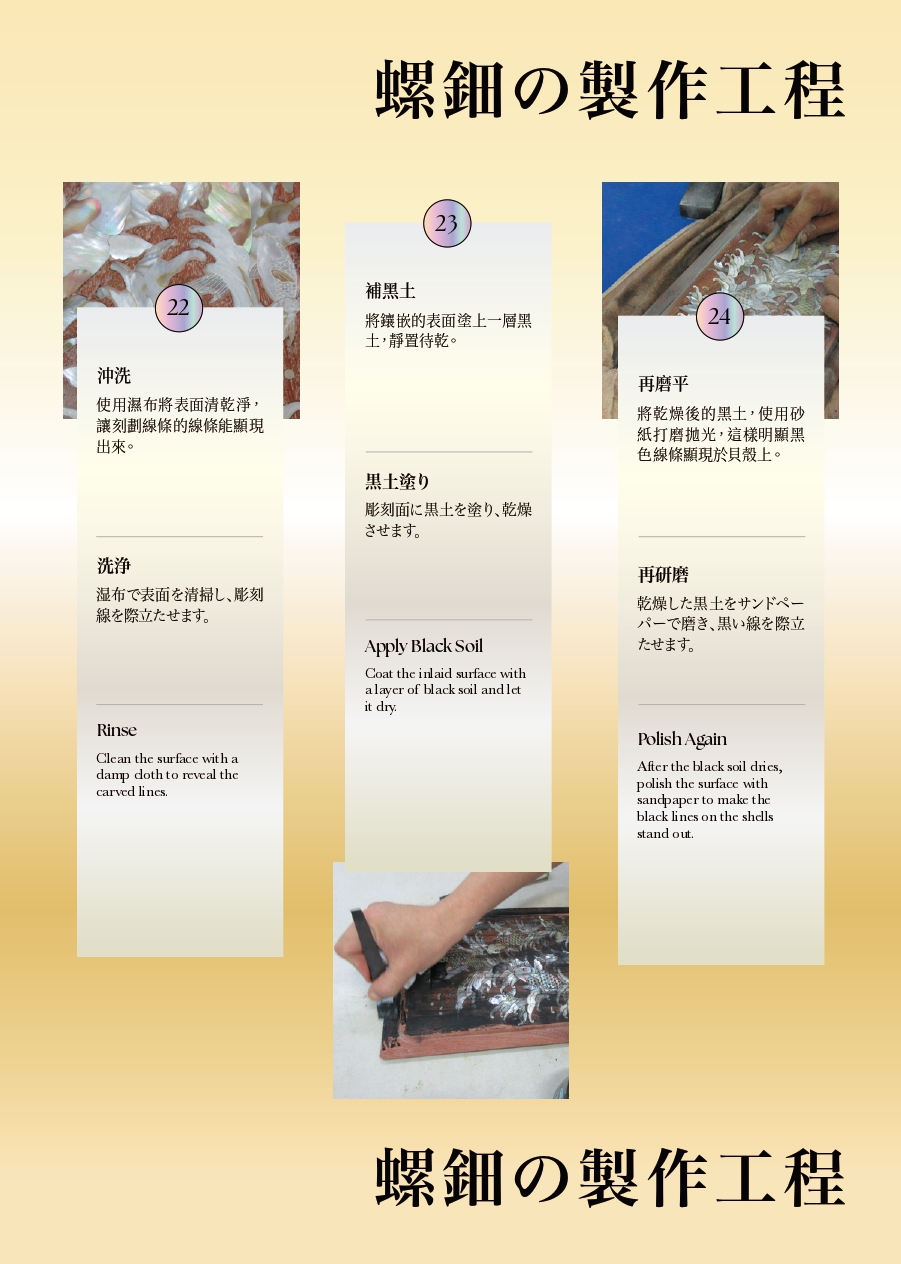

22.清潔:以濕布拭淨表面。

22.Clean: Wipe clean with a damp cloth.

23.補黑土:塗黑土並靜置乾燥。

23.Apply Black Soil: Coat the surface and let it dry.

24.拋磨顯紋:磨去多餘黑土使線紋顯現。

24.Polish Again: Sand to reveal black outlines.

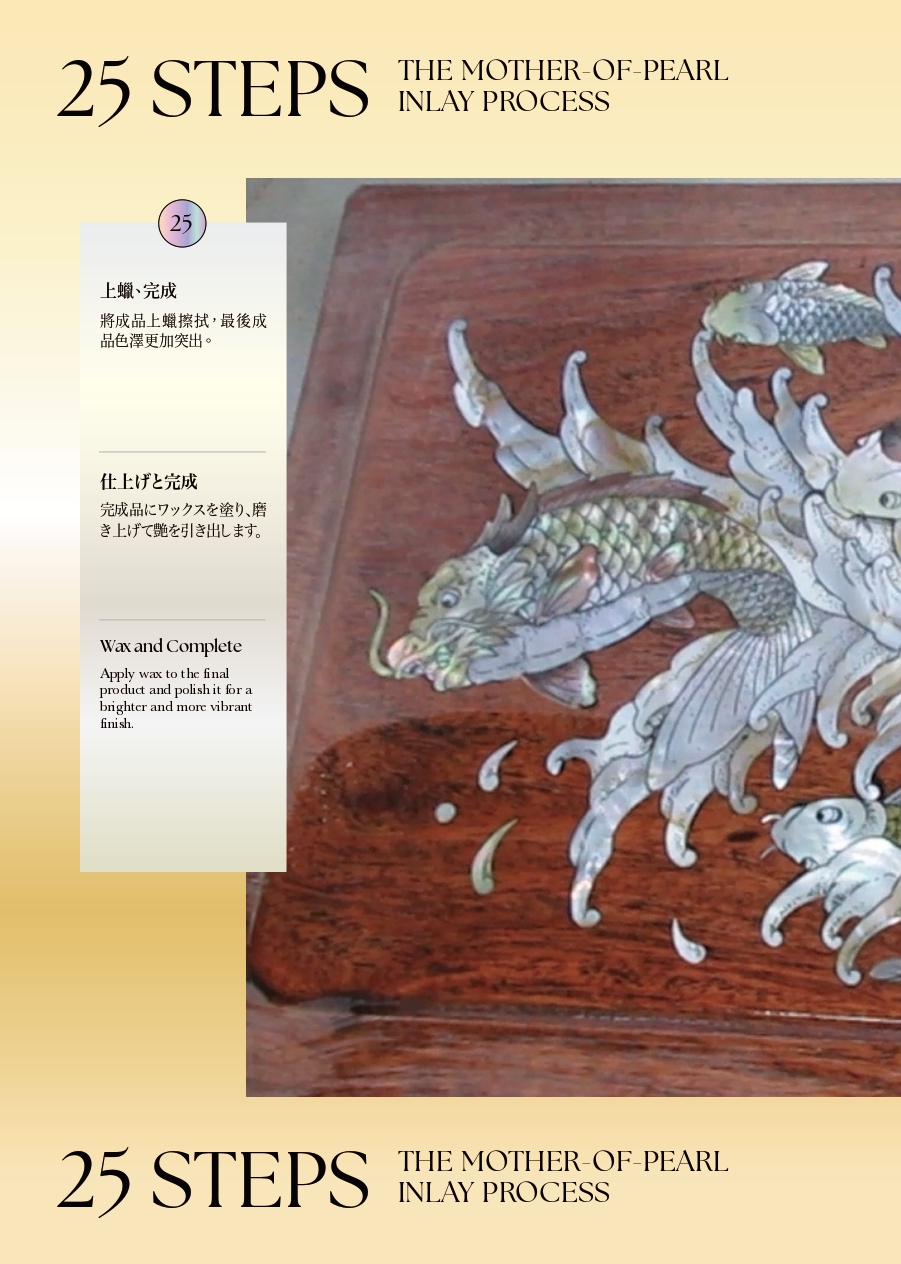

25.上蠟完成:上蠟拋光使色澤亮麗。

25.Wax & Complete: Apply wax and polish to finish.